3D Printer

A Deep Dive into Processing Technology

What does a 3d printer do?

3D printing, also known as additive manufacturing or freeform manufacturing, is a cutting-edge manufacturing technology with outstanding potential for various industries and businesses. By creating objects layer by layer, 3D printing opens up endless possibilities. By using data files, usually from CAD program, you can produce objects in different materials. Common techniques include FDM/FFF (material extrusion), SLA (photopolymerization) and SLS (bonding of powders). Let us guide you through the benefits of 3D printing and how you can get started with this cutting-edge technology.

Based on traditional manufacturing processes, 3d printing offers a:

- Faster path from drawing to prototype

- Sustainable manufacturing with reduced waste

- Cheaper manufacturing

- Design freedom

The benefits of additive manufacturing

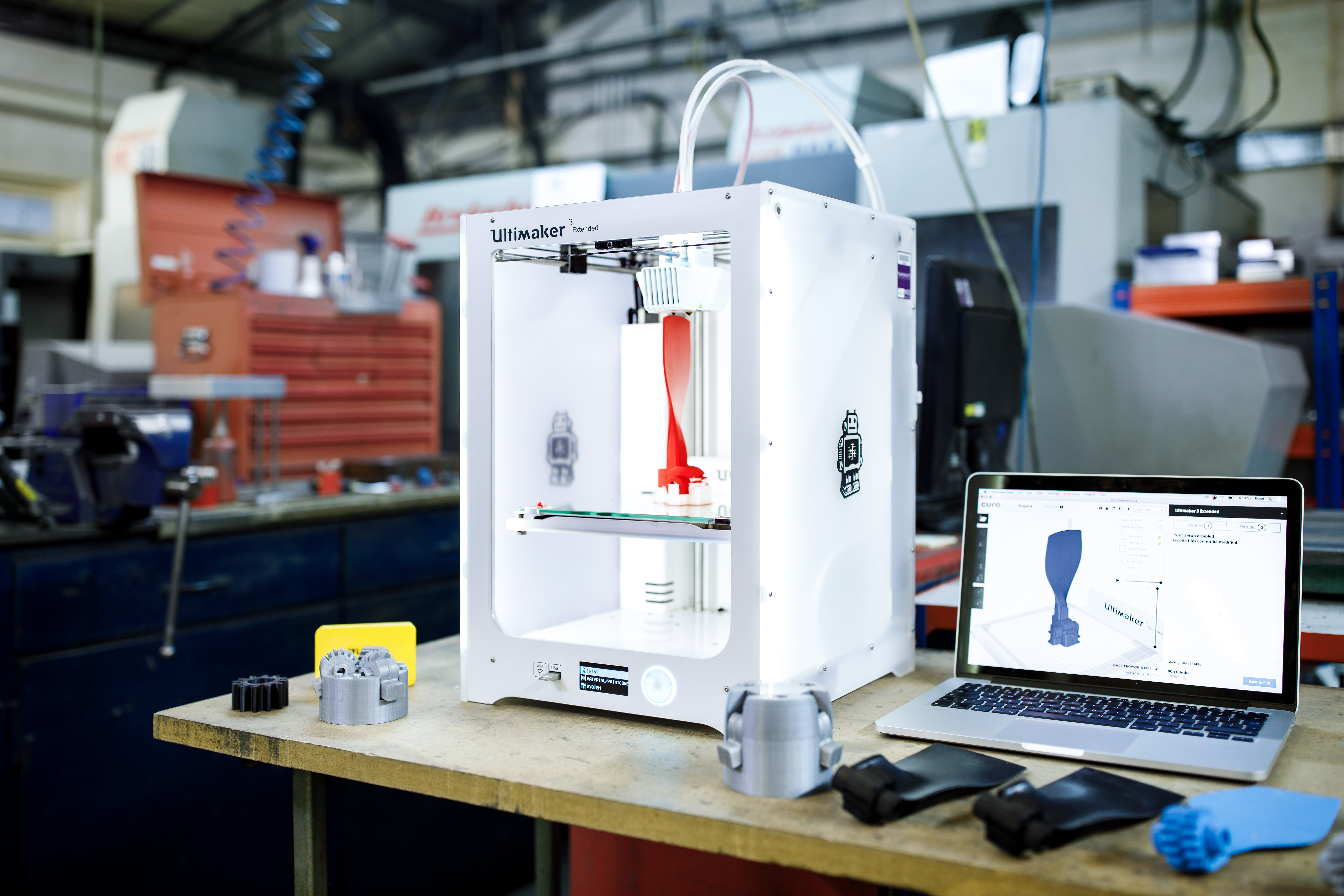

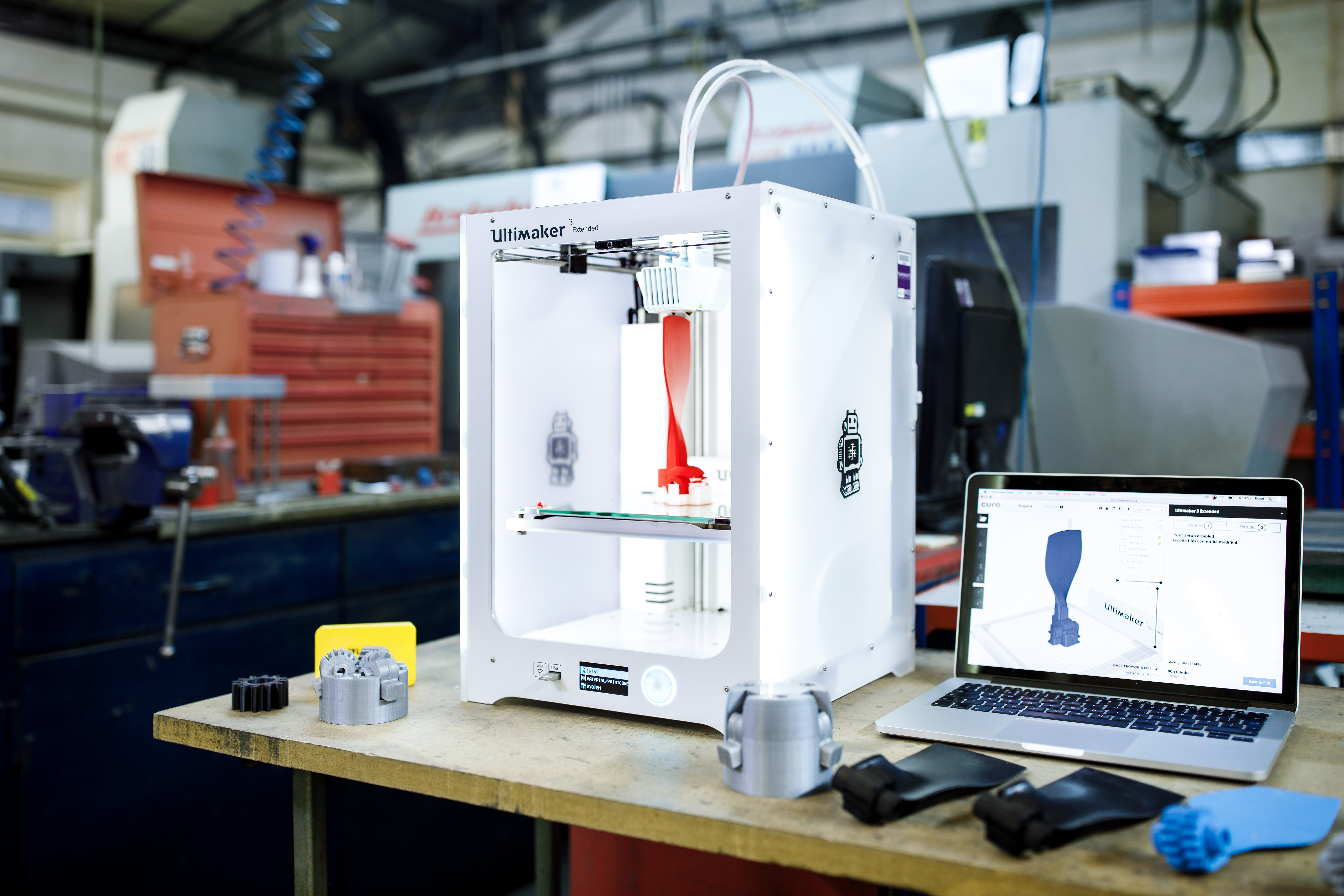

Traditional manufacturing of parts often requires complex processes, different tools and sometimes several machines. Usually, subtractive or formative methods are used. But with 3D printing, a form of additive manufacturing, the whole process becomes more efficient. One of the most common applications is to create prototypes of products, both visual models and fully functional final products. For example, if you need an appliance box for a product, a 3D printer is perfect because you can quickly try and adapt the shape to your needs. With additive manufacturing, components can be manufactured directly according to need, demand and on site.

A fast and cost-effective production

3D printing has never been faster than today, with new technology that is today presented as open source and with regular bases, the development of 3D printers is an increasingly rapid phenomenon. Today, in just a few clicks, it is possible to order home 3d printers that have the potential to produce objects at an industrial level. Through a large variety of materials, it is possible to effectively create prototypes of a model that not only matches the final product aesthetically, but also functionally.

With such cost-effective and fast manufacturing, it can be argued that 3D printing is a step in product development that cannot be opted out of today. That with the fast printing times we have achieved today and with the simple means required to change and make adjustments to a model that perhaps did not quite live up to its expectations.

Common areas of use

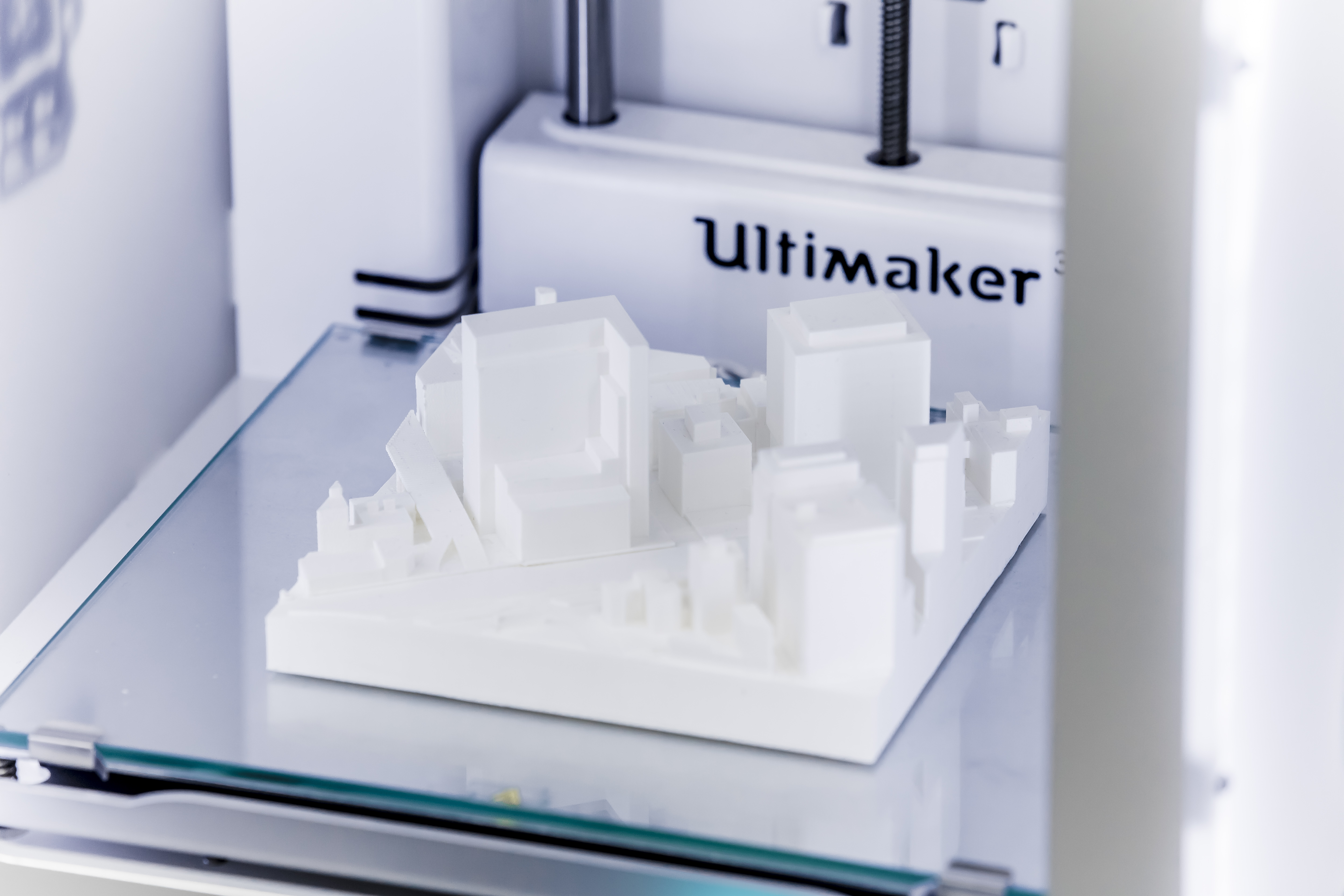

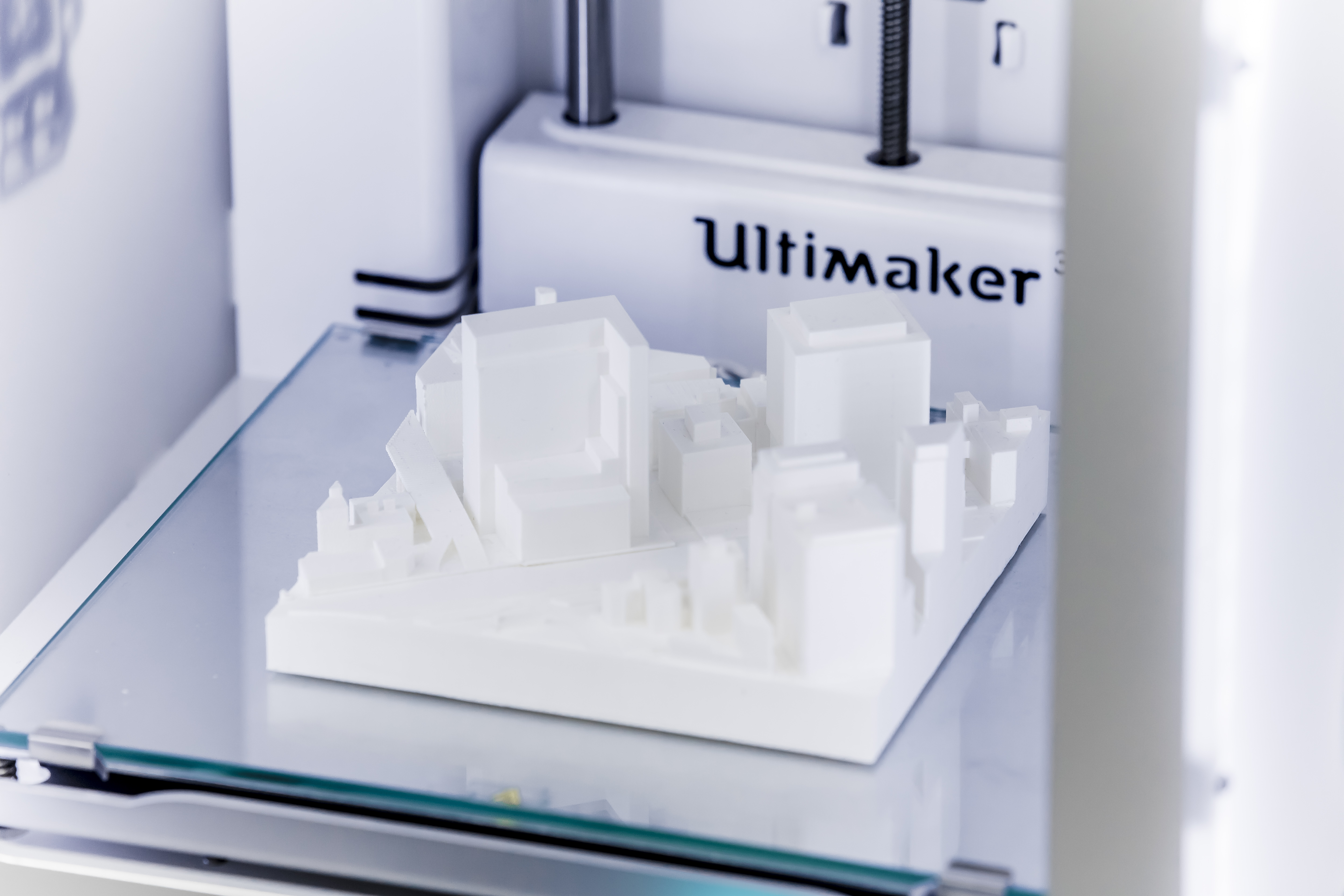

Architecture

3D printing has revolutionized the architecture sector by enabling the design and manufacture of detailed models and prototypes. It provides realistic visualizations for clients and facilitates the testing of building parts in a cost-effective way.

Prototypes

3D printing has revolutionized prototyping by offering a method for designing and creating increasingly complex prototypes. By using 3D printing, you can quickly and efficiently produce physical prototypes that provide a realistic visualization of the product.